Isostatic Pressing Molds for Powder Metallurgy

Categories: Isopressing mold

Application: Isostatic Pressing Molds for Powder Metallurgy

InquiryMain description:

Isostatic Pressing Molds for Powder Metallurgy

Isostatic Pressing Molds for Powder Metallurgy

Isostatic Pressing Molds for Powder Metallurgy

Powder metallurgy is the process of making metal powder or using metal powder (or a mixture of metal powder and non-metal powder) as raw materials, forming and sintering, and manufacturing metal materials, composite materials and various types of products. Powder metallurgy method and the production of ceramics have similar places, both belong to powder sintering technology, therefore, a series of new powder metallurgy technology can also be used for the preparation of ceramic materials. Due to the advantages of powder metallurgy technology, it has become the key to solve the problem of new materials, and plays a pivotal role in the development of new materials.

Isostatic press forming:

1. Can be pressed with concave, hollow and other complex shapes of the rod;

2. When pressing, the relative movement of the powder body and the elastic mold is very small, so the friction loss is also very small. The unit pressing pressure is lower than that of steel molding;

3. Can press a variety of metal powder and non-metal powder. The compact has uniform density, which is especially effective for refractory metal powders and their compounds;

4. High strength compact, easy to process and transport;

5. Mold material is rubber and plastic, the cost is low;

6. Materials that are close to fully dense can be made at lower temperatures

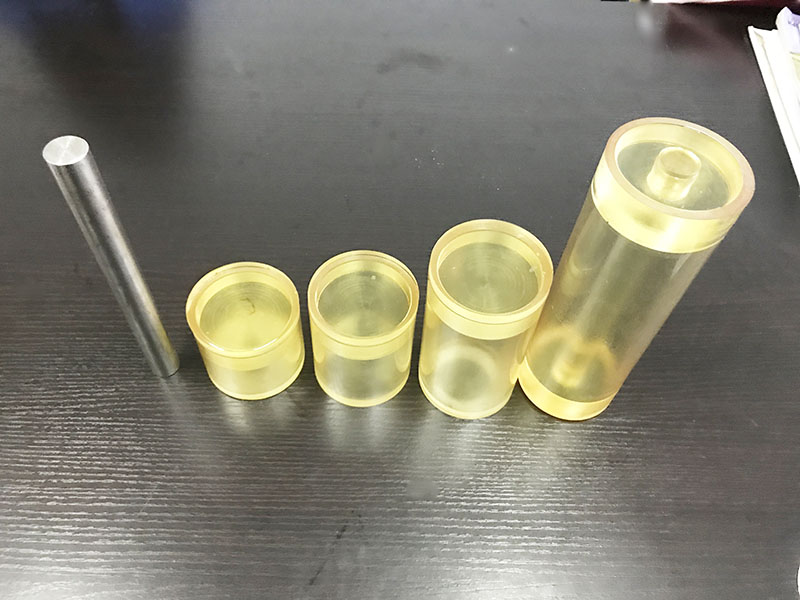

ISO Molds We Made

We support all kinds of customization, if you need it, please contact us.

Phone/whatsapp:+86 18234744811

Email:sales@highindustryco.com